When a concrete structure or paved surface is involved in a fire, it won’t burn. It may, however, “spall.” When this happens, the outer layers of concrete will break apart violently and leave the structure unstable. In some cases, an entire structure may collapse to the ground as a result of intense fire spalling. The good news is, there might be something that concrete installers can do to prevent this from happening in the future.

When a concrete structure or paved surface is involved in a fire, it won’t burn. It may, however, “spall.” When this happens, the outer layers of concrete will break apart violently and leave the structure unstable. In some cases, an entire structure may collapse to the ground as a result of intense fire spalling. The good news is, there might be something that concrete installers can do to prevent this from happening in the future.

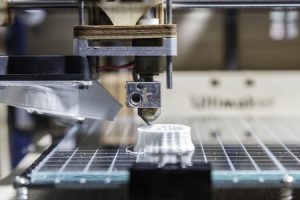

Recently, a few companies have started adding polypropylene fibers to concrete when it’s being poured to stop it from spalling.

These fibers create small channels inside the concrete that allow moisture to escape, thereby preventing the explosive spalling that can take place during a fire. Unfortunately, though, pure polypropylene fibers are quite expensive to produce.

That’s why a team of researchers at the University of Sheffield in England is experimenting with ways to extract polypropylene fibers from the rubber found in recycled tires. If they’re able to develop a cost-effective way to extract the fibers and distribute them evenly in poured concrete, it could make the concrete structures of tomorrow far better able to withstand fire damage.

There’s still more work that needs to be done before we can start using our recycled tires in concrete construction, but it might just be a matter of time before this innovation becomes a practical reality. Until then, you can count on Bergen Mobile Concrete to provide you with the concrete delivery services you need to build durable patios, porches and more on your property. To get started, feel free to give us a call at (201) 797-7550 today!