Concrete driveways are known for being extremely durable and long-lasting, but they can still be damaged in extreme weather conditions. In the winter, when temperatures fall below freezing and snow accumulates on surfaces, concrete driveways can be more likely to experience environmental damage.

Concrete driveways are known for being extremely durable and long-lasting, but they can still be damaged in extreme weather conditions. In the winter, when temperatures fall below freezing and snow accumulates on surfaces, concrete driveways can be more likely to experience environmental damage.

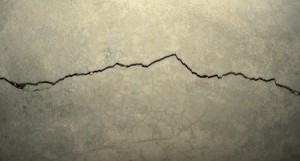

One fairly common type of damage that can occur during the winter is called spalling.

Also known as scaling, spalling occurs when the thin top layer of concrete chips or flakes away from the rest of the paved surface. When scaling becomes widespread, it can eventually expose the aggregate and leave the driveway vulnerable to further damage. In the past, you may have noticed this spalling phenomenon on worn concrete sidewalks that haven’t been repaved in a while.

The good news is, there are steps you can take to prevent spalling on your driveway this winter.

You can start by sealing your driveway to add an extra layer of protection in harsh weather. Sealing products are a great investment that can extend the lifespan of your driveway and prevent environmental damage such as spalling and cracking.

You should also try to limit your use of rock salt and other de-icing chemicals on the driveway. These products do a great job of melting ice on surfaces, but their harsh chemical compositions can accelerate wear on concrete driveways. Instead, use gentler alternatives such as sand, cat litter or alfalfa meal to increase traction on your driveway without causing damage.

All it takes to prevent spalling is a little preparation! Need a hand with your next concrete paving project? Give us a call today to get started!